I took a cotton dyeing class with Jane Woodhouse on the Thursday before Rhinebeck. I had done no natural dyeing except for indigo so I was very excited to get into this class. Jane's classes fill up fast.

When we arrived, we were divided into teams. Each team had two people and I lucked out in that I had a very efficient and complementary partner. The class involves making sample skeins from many different natural dyes - from the lovely purples of logwood to the browns of pomegranate. Each team was given a dye. Most of the dyes were powders but the osage orange was a liquid. We got madder root which interested me but my partner didn't like the color. She loves bright colors and was hoping for logwood or cochineal. Oh well.

We had to make 6 sample skeins with the dye. The first set of three was to dye skeins that had been mordanted with alum acetate. This is a bit different from the alum sulphate that is readily available for pickling and other uses. The skeins had been scoured and mordanted before class. The second set of three skeins was to dye skeins that also had been mordanted with a tannin. There are many tannins and they all leave the fiber a brown color. Tannins are a dye and a mordant. Pomegranate, for example, is both a dye and a mordant.

We briefly soaked the skeins in water because they were getting a little dry. They need to be damp to dye properly. We had to weigh out the dye stuff, mix it in a little very hot water, and then add a specific amount of warm water and the fiber to the dye solution. We mixed everything up in mason jars and then set our first set of dye pots simmering in a water bath. Another very important task was to label each jar with a number that identified it on a master list of the samples. Otherwise the end of the day would have been chaotic!

After the dye pots had been heated to 180F and held there for 30 mins. we carefully lifted them out and set them on the grass to cool. We were in a tent and it was warm so we expanded out into the area surrounding the tent. You can see the thermometer in the dye jar above. The jars were simmered in a water bath in canning kettles. These photos show the sets of three.

Once our first set of three was in the water bath, we did the same thing for the second set of three samples. The reason for the sets of three was that each dye stuff was going to yield a sample of its natural color, then one modified with iron (ferrous sulphate) and one that would be over-dyed with indigo.

We

When we arrived, we were divided into teams. Each team had two people and I lucked out in that I had a very efficient and complementary partner. The class involves making sample skeins from many different natural dyes - from the lovely purples of logwood to the browns of pomegranate. Each team was given a dye. Most of the dyes were powders but the osage orange was a liquid. We got madder root which interested me but my partner didn't like the color. She loves bright colors and was hoping for logwood or cochineal. Oh well.

We had to make 6 sample skeins with the dye. The first set of three was to dye skeins that had been mordanted with alum acetate. This is a bit different from the alum sulphate that is readily available for pickling and other uses. The skeins had been scoured and mordanted before class. The second set of three skeins was to dye skeins that also had been mordanted with a tannin. There are many tannins and they all leave the fiber a brown color. Tannins are a dye and a mordant. Pomegranate, for example, is both a dye and a mordant.

We briefly soaked the skeins in water because they were getting a little dry. They need to be damp to dye properly. We had to weigh out the dye stuff, mix it in a little very hot water, and then add a specific amount of warm water and the fiber to the dye solution. We mixed everything up in mason jars and then set our first set of dye pots simmering in a water bath. Another very important task was to label each jar with a number that identified it on a master list of the samples. Otherwise the end of the day would have been chaotic!

After the dye pots had been heated to 180F and held there for 30 mins. we carefully lifted them out and set them on the grass to cool. We were in a tent and it was warm so we expanded out into the area surrounding the tent. You can see the thermometer in the dye jar above. The jars were simmered in a water bath in canning kettles. These photos show the sets of three.

Once our first set of three was in the water bath, we did the same thing for the second set of three samples. The reason for the sets of three was that each dye stuff was going to yield a sample of its natural color, then one modified with iron (ferrous sulphate) and one that would be over-dyed with indigo.

We

Here we are adding the ferrous sulphate and stirring. Iron dulls the color but sometimes that is what you want. Once the jars had cooled somewhat, we removed the skeins, rinsed them and hung them up to dry. Fortunately, there is a nice fence next to the tent which Jane uses every year as a drying rack. I've admired the skeins in past years.

Our tannin mordanted skeins went in next into the water bath. Then we did a couple of things in parallel. Jane had built an indigo dye pot but it needed to be refreshed and checked so she went off to do that. The rest of us started on the third set of samples.

The third set had to do with dyeing with stock solutions. Unlike synthetic dyes, natural dyestuffs do not have a fixed amount to yield a 1% stock solution. The dye manufacturer will provide a guide on each jar based on its strength. Jane had given us some combinations to make to create other colors that weren't possible with one single dye. We created the stock solutions, which didn't use all the dyes that we had used earlier. They used a subset. Then we carefully measured out the correct amounts of the stock solution for each color using syringes. These were added to mason jars (again labeled with the number of the formula) and then we put one each of the two mordanted skeins. One was the alum only and the other was the tannin+alum.

Once these were simmering in the water bath, we started dyeing our earlier samples in the indigo dye bath. It was interesting to see that the tannin samples barely picked up the indigo. Tannins are acid and indigo likes an alkaline environment to dye fiber.

One result of doing this in a single day class was that we didn't get the full depth of color. Almost all dyes take a while to absorb as the dye bath cools down and we should have really left the skeins in overnight to get the maximum color. Similarly, indigo does best with multiple dips with drying and oxidizing time between dips. We did a couple of dips for some of the samples but most got just one dip in the indigo.

Once our skeins were mostly dry, we cut them into pieces and labeled them with the number. This is where my partner and I collaborated brilliantly. We got ours done and then helped other teams who were slower. By this time, the class was tired and the whole process of creating the individual samples and labeling them and finally picking up a set of them created some frustration and flouncing.

These were the tables with the samples laid out. We each had to pick up one piece from each skein. I decided to wait till everyone was done as there was a huge crush around the table. As a result, it was almost dark by the time we were done and I am missing 1 or 2 samples.

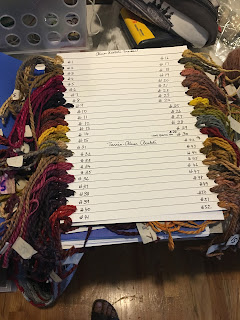

When I got home, I just laid out the samples to finish drying as some of them were still damp. A couple of weeks later I got some cardstock and punched holes in it, and wrote down all the numbers of the dyes and combinations we created. I then attached each skein to its number on the card.

I have 3 sheets of card that look like this. But at least everything is organized and I can look up any sample and its constituent formula easily.

All in all a really educational day. I realized that natural dyes are not that different from synthetic dyes except that there is no guarantee on the exact color. The mineral content of your water makes a difference as well as the strength of the dye stuff. We used manufactured dye powders/liquids in this class and at least there, the manufacturer has tested the strength and given us an indicator as to that. When one dyes with natural substances from one's garden or kitchen, there is even more variability in the color.

I collected marigold and black eyed susan blooms from the garden this summer and they are in the freezer along with some pomegranate skins. I also have some dye plants called pernilla that we weeded out of the dye garden at the fairgrounds. It grows everywhere and we pulled it out from where it didn't belong. I plan to simmer them and use them to dye wool this winter. It should be an interesting experiment.