I have been in a spinning mood. I am winding a warp for the floor loom but mostly I've been spinning.

I'll start with the knitting as it is easier. I finished the red fingerless mitts with some leftover yarn. They only needed the thumbs. The thumbs are fat because the yarn is thicker but when I wear them, they are OK.

My spindle spun thick yarn is plied. I had to hand wind it onto the bobbin for the last few yards as it wouldn't wind on because the bobbin was so full. But I didn't want to make a skein for a few yards. So I persevered and managed to finish it. This is lac and cochineal dyed roving from Handspun by Stefania. I got it some years ago at Rhinebeck.

I also finished the little Navajo rug. It looks crooked because I let the sides draw in too much so the fell line (where the weaving ends) got tilted. I filled it in with black but as a result, the rug looks crooked. I am pretty pleased with it.

I have also finished spinning an Onyx-to-Crimson gradient from Fiber Optic. But all you see is black on the bobbin so I will post pictures after it is plied.

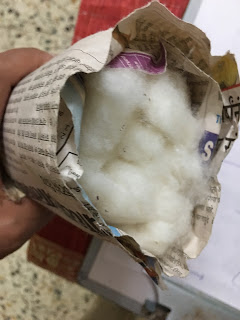

I also plied and semi-finished a small cotton sample skein on the charkha. One is supposed to boil cotton in an alkaline bath to finish it. I didn't want to do that for a small skein so I will spin some more and finish it all. I just soaked this in a warm water bath. It is a bit thick and thin but seems to be yarn.

I spent some time pondering how to ply this. There is a built-in lazy kate on the Bosworth charkha but the angle from that to the spindle is a bit weird. Maybe I will use that another time when I have more confidence. I ended up winding a 2-ply plying 'ball' on a soft foam core left over from some yarn. I could have put this on my lazy kate but I decided to just let it roll around on the floor. It worked well although there is too much plying twist in the yarn.

That is what I've been up to. Next up is warping the floor loom and plying the gradient. Plus I am going to swatch for a sweater, and am spinning more cotton and spindling the purple cashmere/silk. I will finish up the travel next week.

I'll start with the knitting as it is easier. I finished the red fingerless mitts with some leftover yarn. They only needed the thumbs. The thumbs are fat because the yarn is thicker but when I wear them, they are OK.

I also started these flip-top fingerless mittens in India but they've been languishing. I really don't like knitting mittens. Anyway they are done. They match the practice scarf I did on the floor loom. The yarn for the mittens is the weft although I used a little of the warp when I ran out of yarn. You can see that in the top of the left mitten.

My spindle spun thick yarn is plied. I had to hand wind it onto the bobbin for the last few yards as it wouldn't wind on because the bobbin was so full. But I didn't want to make a skein for a few yards. So I persevered and managed to finish it. This is lac and cochineal dyed roving from Handspun by Stefania. I got it some years ago at Rhinebeck.

I also finished the little Navajo rug. It looks crooked because I let the sides draw in too much so the fell line (where the weaving ends) got tilted. I filled it in with black but as a result, the rug looks crooked. I am pretty pleased with it.

I have also finished spinning an Onyx-to-Crimson gradient from Fiber Optic. But all you see is black on the bobbin so I will post pictures after it is plied.

I also plied and semi-finished a small cotton sample skein on the charkha. One is supposed to boil cotton in an alkaline bath to finish it. I didn't want to do that for a small skein so I will spin some more and finish it all. I just soaked this in a warm water bath. It is a bit thick and thin but seems to be yarn.

I spent some time pondering how to ply this. There is a built-in lazy kate on the Bosworth charkha but the angle from that to the spindle is a bit weird. Maybe I will use that another time when I have more confidence. I ended up winding a 2-ply plying 'ball' on a soft foam core left over from some yarn. I could have put this on my lazy kate but I decided to just let it roll around on the floor. It worked well although there is too much plying twist in the yarn.

That is what I've been up to. Next up is warping the floor loom and plying the gradient. Plus I am going to swatch for a sweater, and am spinning more cotton and spindling the purple cashmere/silk. I will finish up the travel next week.